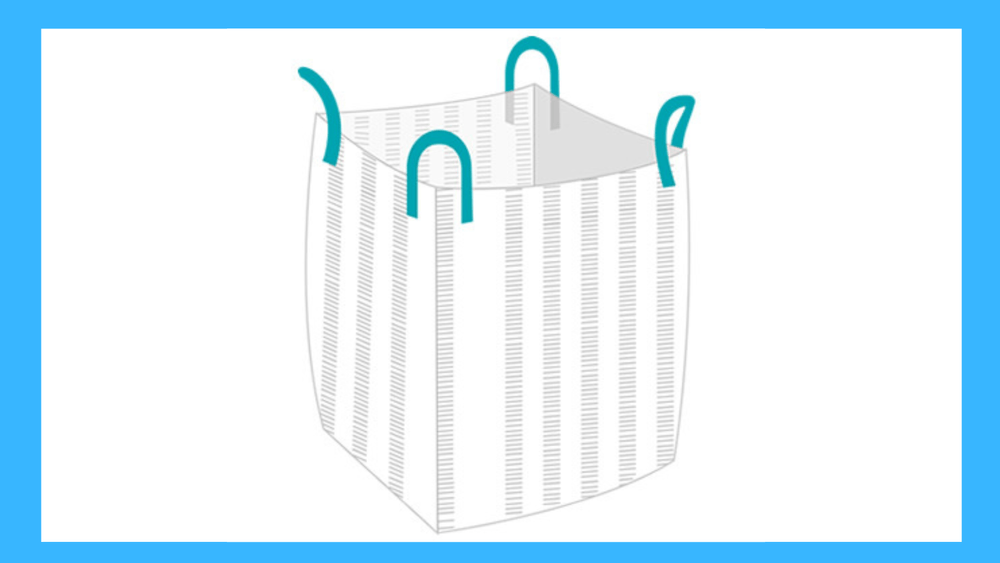

FIBC Bags

Uniplast takes pride in being a premier manufacturer of Flexible Intermediate Bulk Containers (FIBCs)

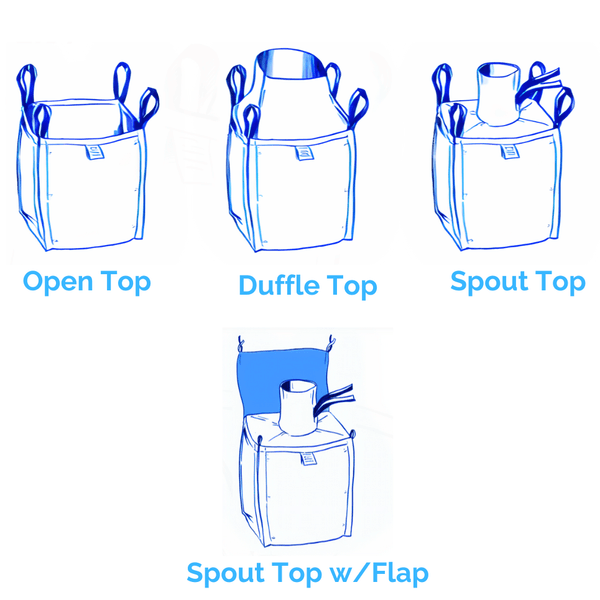

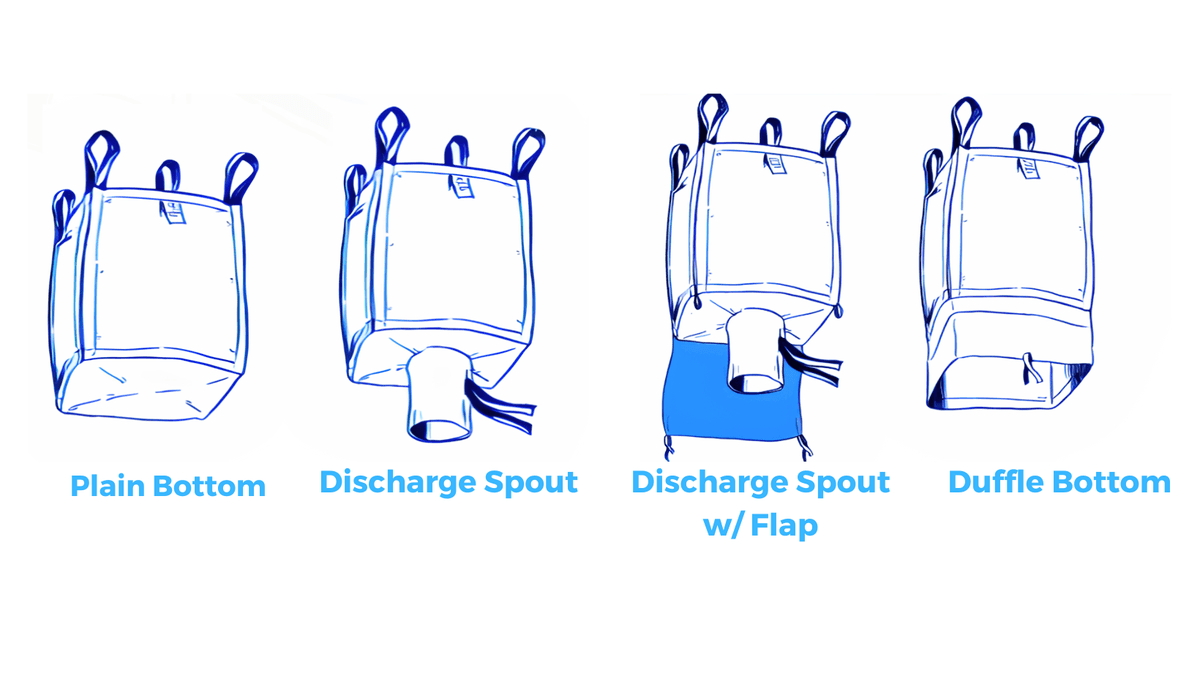

Trust Uniplast to deliver FIBCs that align seamlessly with your distinct needs, providing reliable solutions on a global scale.

%100 VIRGIN POLYPROPYLENE